Trust the Real-Time Data That Drive Operations

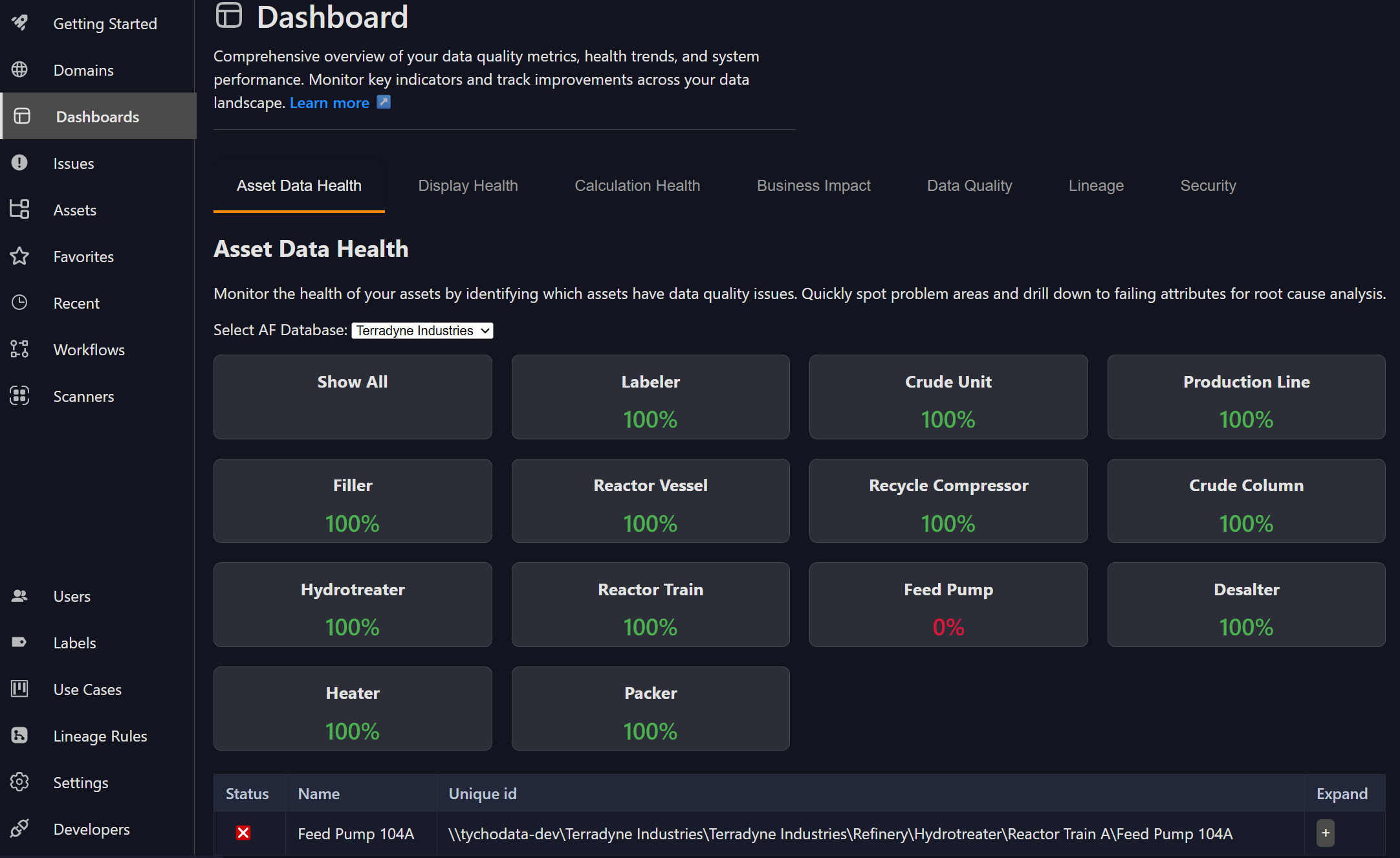

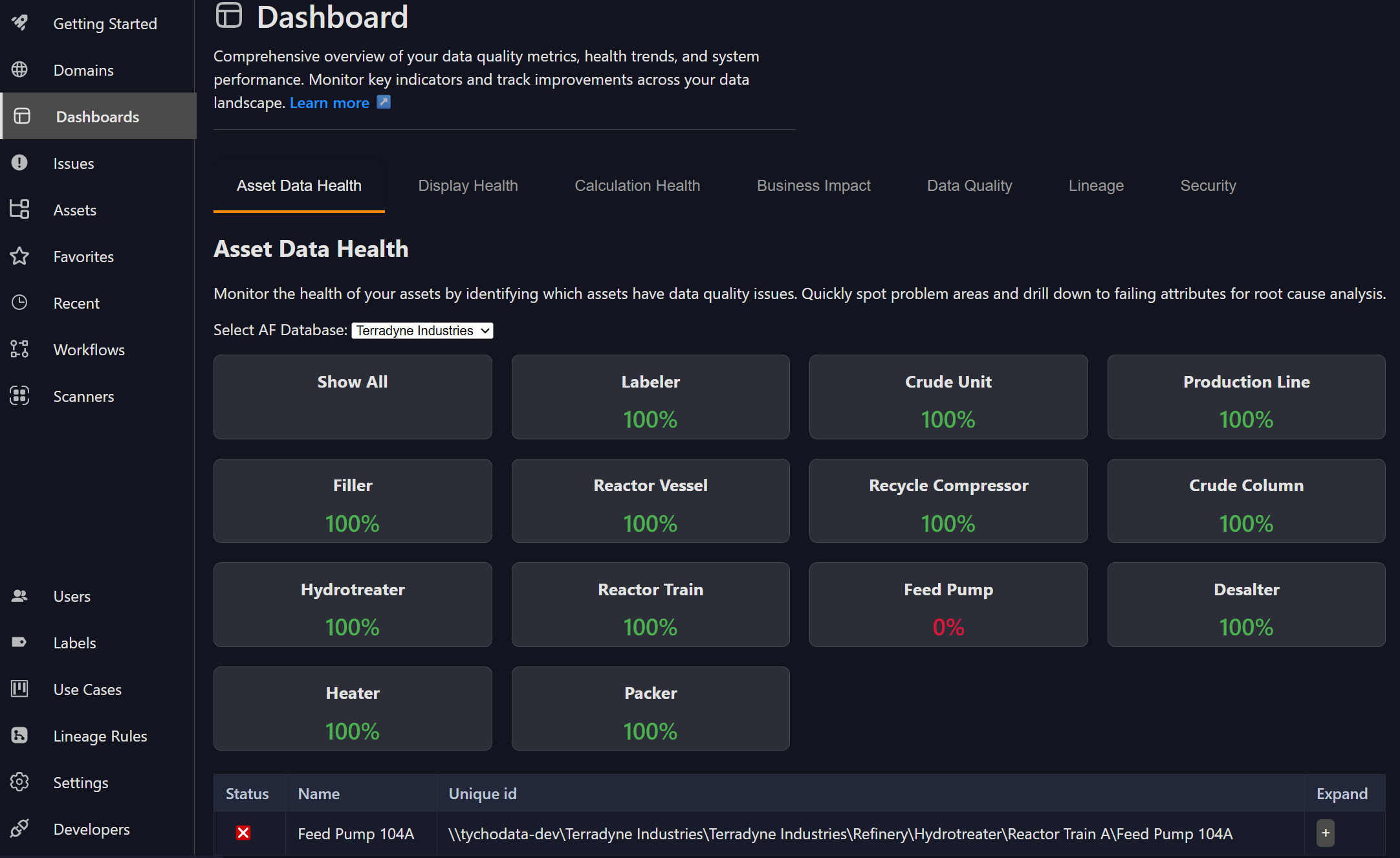

Automatically detect PI data quality issues before they trigger false alarms or create blind spots in operations

Detects issues early so bad data does not drive decisions.

Show when data is good and when it is suspect, before operators act on it.

Decision support automates monitoring and accelerates data downtime resolution.

Proactively monitor mission-critical data streams feeding into AI applications, reporting, and operator displays

Osprey transforms data quality from a technical challenge into a competitive advantage, enabling faster decisions, reduced risk, and improved operational performance.